Technology

| all | Increase the success ratio of a production using a wetting tension of a substitute index for the adhesive strength (R4) |

|---|

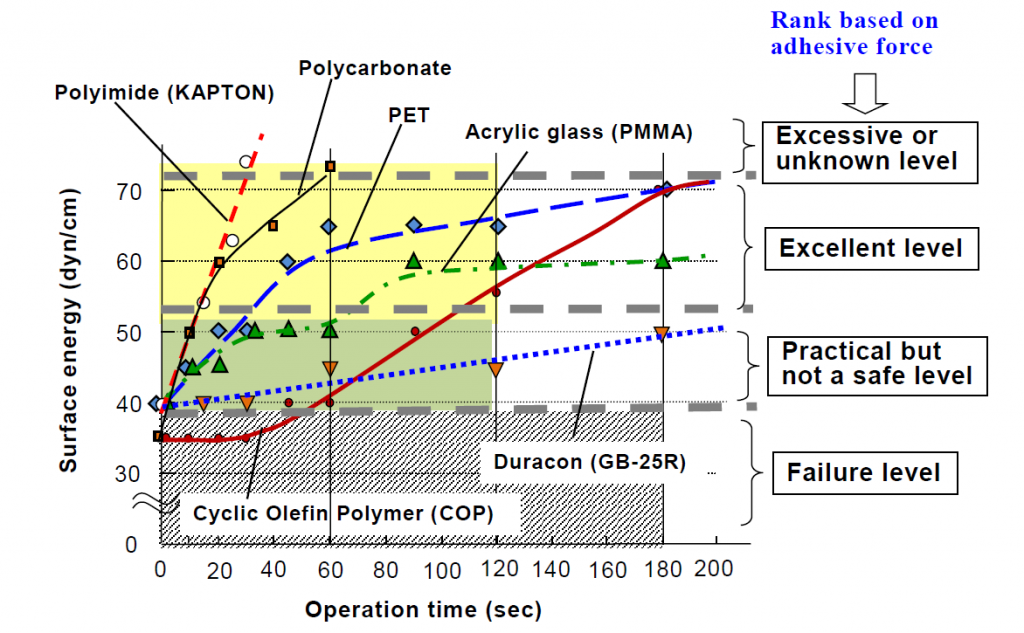

Conditions :

Processing equipment: UV/Ozone Surface processor (SSP16-110)

Gap between an lamp and the work=30mm,

UV irradiance : 15.9mW/cm2 (254nm, UV meter: 25・36-3/SEN)

Fig 1. Change of the surface energy in accordance with UV/Ozone surface processing

Table1.Ranking surface energy dyne level concerning to the adhesion

| Ranking of the adhesive ability |

Surface energy (Dyn/cm) |

Summary of the performance of the adhesion |

|---|---|---|

| Failure level | <38 | Surface tension level is too low to achieve a practical adhesion force. |

| Practical but uncertain level |

39-50 | Dyne level which can achieve practical adhesion force. However, it is not safe level; it may lead to lack of adhesion force due to effects of storage conditions after UV surface treatment or other inappropriate handling. |

| Excellent level | 54-72 | This level enables maintaining adhesiveness during storage for as long as several weeks and can avoid effects by uncertainness of measurements of surface tension. Dyne value of 72 is equal with 0 degree contact angle of a water drop on glass. It shows the status where the organic contaminant layer became thinner and the ground face of glass started to be exposed. |

| Excessive or unknown level |

>72 | Caution!:Not to overdose UV on surface, otherwise the surface energy of a substrate and glue will be reversed. This leads to reverse the surface adhesiveness again. |

Fig 2.The relationship between the surface energy and UV/O3 processing time.

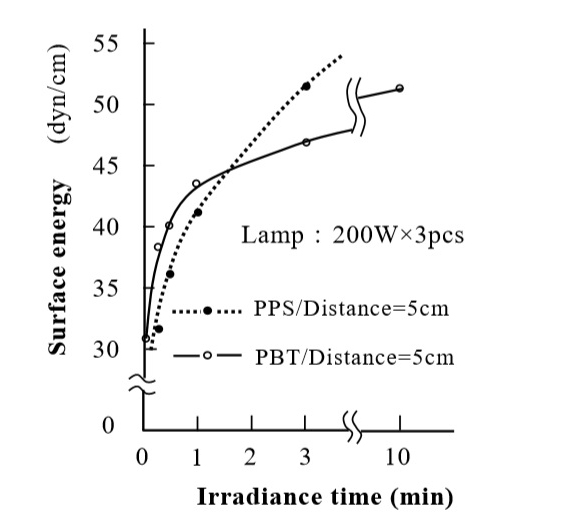

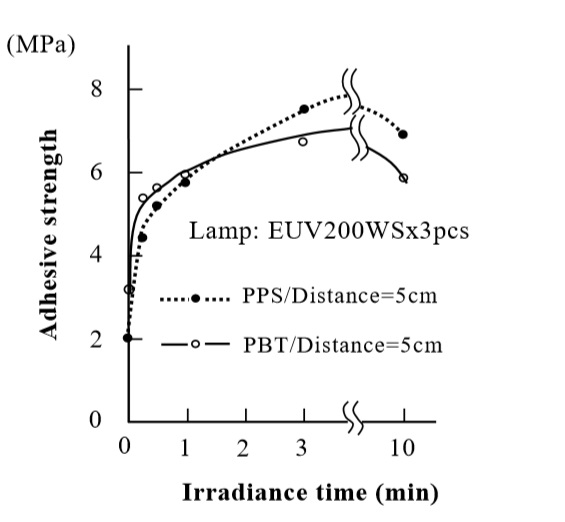

Fig 3.The relationship between adhesive strength and UV/O3 processing time

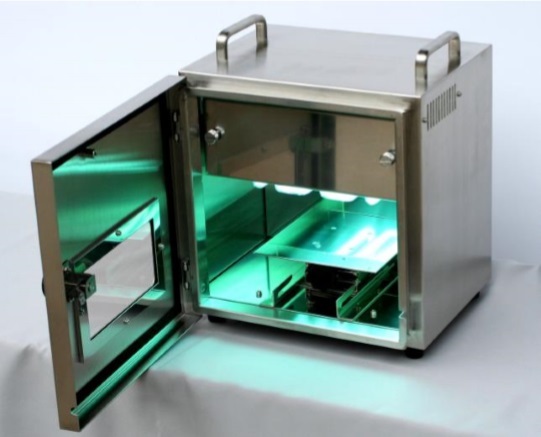

Fig 4.The UV light unit of UV/Ozone surface processor (SSP16-110) used for the test. Size of a UV light unit : 300×250×300H(mm)

Size of a lamp face:160×160(mm)

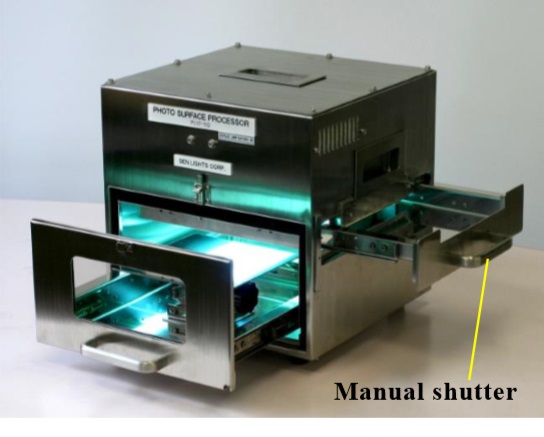

Fig 5.The sister product (SSP17-110) of the SSP16-110 is equipped with a manual shutter. . Size of a UV light unit : 300×290×310H(mm)

Size of a lamp face : 160×160(mm)